We are in the midst of what some refer to as Industry 4.0 – the fourth industrial revolution. Technological advancements in fields such as data, analytics, collaboration, scalability and connectivity are driving not just innovation, but true paradigm shifts in manufacturing and the delivery of products and services. Developing technologies such as artificial intelligence and machine learning, big data, cloud computing, augmented and virtual reality, new materials, 3D printing, and the Internet of Things – and, perhaps more importantly, the ways in which these various factors can interact – present not just an opportunity, but a necessity for businesses to adapt to a new industrial reality.

Inevitably, these technologically driven shifts will result in a seismic transformation in the way many organizations go about their day-to-day business. This will require a cultural change that will affect the workforce and leadership, and feed into factors such as product innovation, manufacturing efficiency, supply chain performance, compliance and, naturally, quality. This is where Quality 4.0 comes in. The core concept of Quality 4.0 is about aligning the practice of quality management with the emerging capabilities of Industry 4.0; to help drive organizations toward operational excellence.

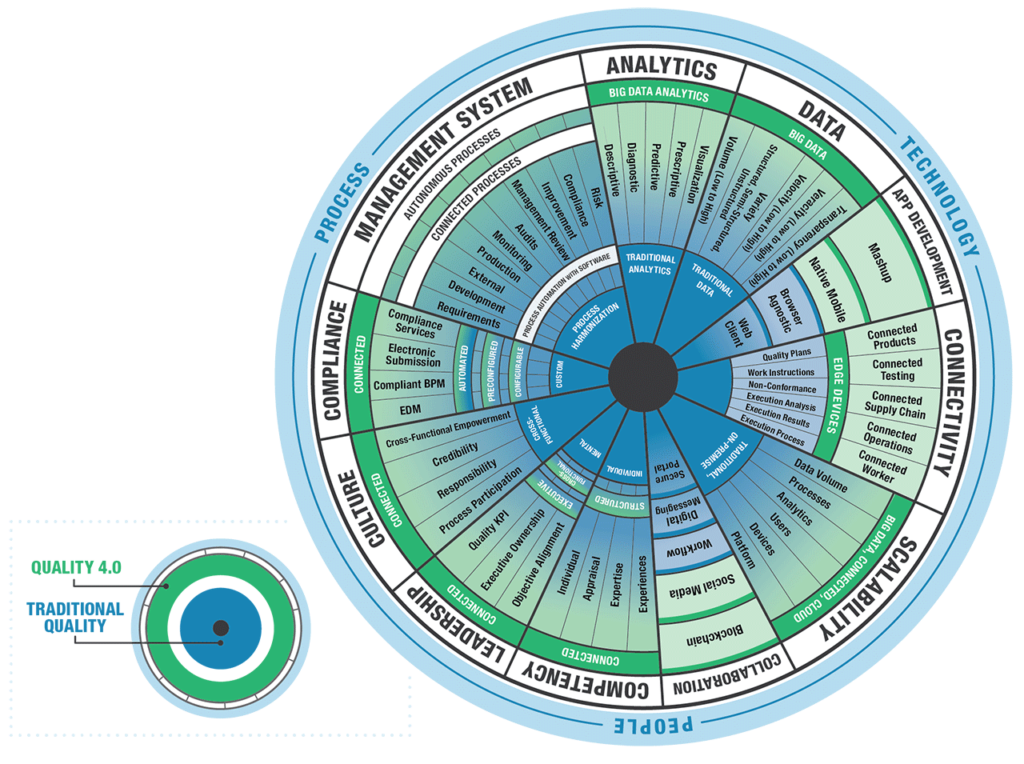

The 11 Axes of Quality 4.0

Business analysis carried out by LNS Research identifies the 11 key components, or “axes” of the Quality 4.0 framework. Getting to grips with these axes – which include both familiar quality considerations and others that may be less familiar – will help your organization move toward the adoption of Quality 4.0 as the bedrock of your quality management systems.

Data

In the quality sphere, data has always been a vital driver for improvement. However, for most organizations there is still a lag in the process of data collection, analysis, and decision-making. Technological advances in Industry 4.0 – such as advanced analytics, artificial intelligence and machine learning – can help organizations achieve real-time visibility of vital quality metrics such as internal engineering and manufacturing performance, supplier performance, and customer service. A key element of Quality 4.0 is the swift, effective collation of data from various sources to empower informed and agile decision-making.

Analytics

According to LNS Research, 37% of organizations identify poor metrics as the main roadblock to achieving quality objectives. Current quality metrics are primarily descriptive at their core – they provide information on what happened, why it happened, and use predictive models to say what is likely to happen as a result. Industry 4.0 technologies including big data, machine learning and artificial intelligence allow a fourth category to be added to the current descriptive/ diagnostic/predictive framework: prescriptive. Machine learning and artificial intelligence insights allow prescriptive analytics to predict failure and inform what action to take to change the outcome.

Connectivity

In terms of Quality 4.0, connectivity refers to the connection between business information technology (IT) and operational technology (OT). For context, IT refers to tools such as enterprise quality management systems, enterprise resource planning, and product lifecycle management, while OT is the technology used in manufacturing, laboratory and service environments. Relatively inexpensive sensors can link up connected people (via smart devices or wearables), products (for example, providing performance feedback across their lifecycle), edge devices (which can perform local analytics without overburdening central OT systems), and processes. Leveraging connectivity can allow for the collection of real-time or near real-time feedback.

Collaboration

Enterprise quality management system (EQMS) software can help organizations to streamline and synthesize quality practices to improve compliance and increase efficiency. However, according to LNS Research, only 21% of organizations have adopted a core EQMS, leaving the vast majority of businesses utilising emails, automated workflows and portals to manage quality activities. Quality 4.0 can leverage new tools and practices – such as social listening and blockchain – to gain insights into factors such as customer satisfaction, and greater visibility of parts’ and products’ movement through supply chains.

App development

In a world of smartphones, tablets and wearable devices, apps are increasingly becoming a part of everyday life both for individuals and for organizations agile enough to take advantage of trends. But more than this, apps are an ever more important tool for brands to connect with customers – as well as employees and other stakeholders – and gather vital data and feedback. Advanced apps that utilize tech such as augmented reality and virtual reality have considerable potential in the Industry 4.0 workplace.

Scalability

According to LNS Research 37% of organizations cite fragmented data sources and systems as their main challenge in achieving quality objectives. Lack of scalability renders organizations – regardless of whether they adhere to traditional quality management practices or Quality 4.0 – unable to fully and effectively reconcile processes, competencies and best practices. One of the principal Industry 4.0 tools that can help in achieving scalability is cloud computing – whether that’s software-as-a-service (SaaS), infrastructure-as-a-service (IaaS), or platform-as-a-service (PaaS).

Management systems

As noted previously, only 21% of organizations have adopted an enterprise quality management system – despite the benefits they can deliver in terms of scalability, connecting quality processes and providing centralized analytics. To fully reap the benefits of Quality 4.0, organizations should look to automate processes with software, and harmonize and connect these automated processes with other systems and operations. Improving system autonomy will reduce the time high-value staff and management spend on execution and allow them to shift focus toward improvement and innovation.

Compliance

Quality 4.0 provides a variety of tools and techniques that can be implemented to automate compliance activities. Through social collaboration, organizations can share successful compliance approaches across different divisions and work sites. Meaningful data analytics can alert organizations about potential compliance breaches; allowing for preventative action to be taken. Integration of business information technology and operational technology can help to automate compliance-related tasks and data collection. Quality 4.0 allows organizations to assess current compliance strategies and identify opportunities for improvement.

Culture

Many organizations like to think that they promote and engender a “culture of quality.” However, according to LNS Research, only 13% of cross-functional teams clearly understand how quality contributes to strategic success. By connecting data, analytics and processes and thereby improving visibility, connectivity, collaboration and insights, Quality 4.0 makes a true organization-wide culture of quality more attainable.

Leadership

Those who work in quality roles believe in its importance to organizational success, but that attitude doesn’t always permeate up to senior leadership. According to LNS Research, only 37% of organizations believe quality is critical for customer satisfaction, 26% agree that the quality function has a clear and compelling role in delivering corporate strategy, while just 13% said that quality is a priority for top management. Quality 4.0 represents an opportunity for quality teams to clearly align their objectives and practices with strategic aims.

Competency

Quality 4.0 encapsulates a variety of technologies that can be utilized to improve competency. Social media tools can be leveraged to share lessons and experiences across organizations, and even between organizations. Outputs from artificial intelligence and machine learning systems can be utilized to develop new expertise, while artificial reality (AR) and virtual reality (VR) systems can be used to improve workers’ expertise. Smart devices and wearables can assist in employee appraisal, while learning management systems, AR and VR can be deployed to improve training delivery.

Why is Quality 4.0 important?

It would be a mistake to believe that the range of technologies that together contribute to Industry 4.0 are anything less than transformative in nature. Quality 4.0 represents an opportunity to utilize those Industry 4.0 technologies to realign quality functions with broader organizational strategy.

From a base position where only 13% of organizations believe that quality is a priority for top management, Quality 4.0 provides the scope to both redirect quality activities and to alter the perception of the quality function in organizations as being little more than the “quality police.”

Developing an effective Quality 4.0 strategy will enable organizations to address long-standing quality issues. For many organizations, these stem from inefficiencies resulting from issues such as lack of cross-functional ownership, ineffective communication, and fragmented traditional quality systems. With some 37% of organizations citing fragmented data sources and systems as a top challenge in achieving quality objectives, the concept of Quality 4.0 presents an opportunity for organizations to review the root causes of current barriers to quality success, and engage in strategic planning to explore how new technologies and the advantages they deliver – such as improved data transparency and high quality data-driven insights – can be leveraged to achieve a culture of excellence.