An effective Supplier Quality and Development system can help organizations save money, reduce risks, and generate superior quality products that delight customers and stakeholders alike. However, some organizations don’t have the tools and methods in place to monitor and improve their suppliers’ processes, which can create unnecessary financial risks.

If a production stoppage occurs, an organization with a “poor-quality” mindset – the assumption that quality is inherent in the supplier management process – may not know how to correct it. This can have a detrimental impact on the organization’s bottom line and reputation, especially if customers require credit for undelivered products. In the majority of cases, it will also lead to products being scrapped and reworked, and a high level of supplier-related cost of poor quality (COPQ).

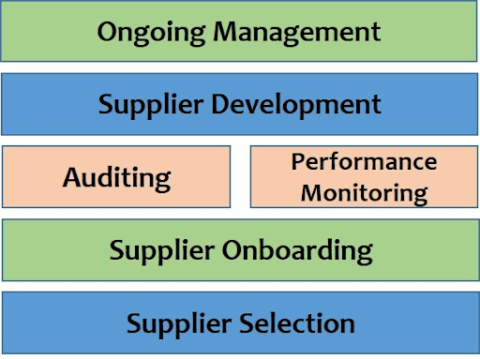

In his blog series, Peter will take readers through the six components of our Supplier Quality and Development Model, as visualized below: