How do you find process capability?

- Identify the process subjects for measurement.

- Establish units of measure, sensors, and upper and lower specification limits for the selected subjects.

- Operate the process through a number of cycles. (A minimum of 40 observations without any assignable causes are usually needed.)

- Identify and remove any observations that are out of control as the result of assignable causes.

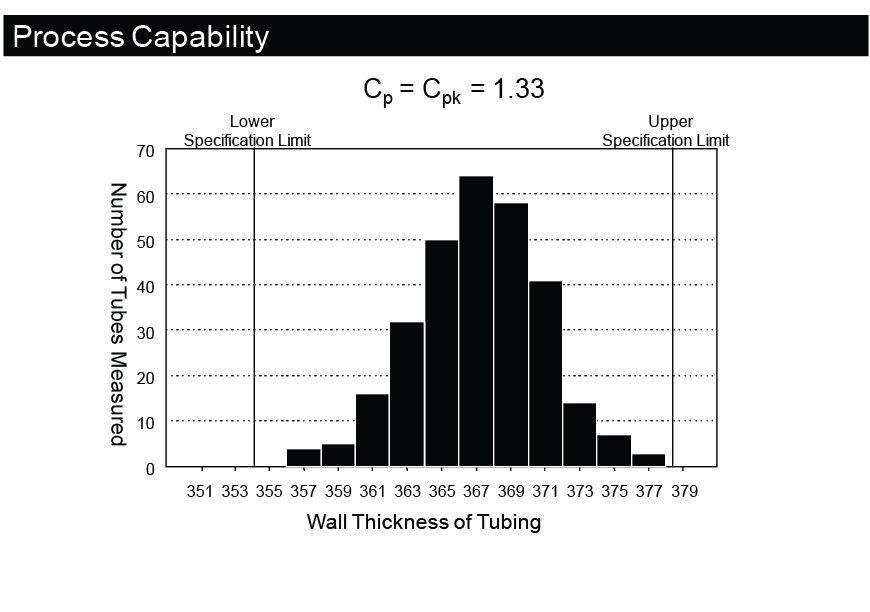

- Construct a histogram of the remaining observations for each subject.

- Evaluate the process capability visually.

- Calculate the Cpk index for each process subject.

The index must, at a minimum, equal 1. 0. Most processes should have a minimum index of 1.33. - If the process is not capable, identify and eliminate the root causes for excessive variability.

For more information on process capability and how Juran can help you leverage it to improve your quality and productivity, please get in touch with the team.

| Check out Juran’s LSS Training Courses |

| Lean Six Sigma Yellow Belt |

| Lean Six Sigma Green Belt |

| Lean Six Sigma Black Belt |

| Upgrade to Black Belt |

| Lean Six Sigma Master Black Belt |

| Lean Expert Program |