What is Lean?

Lean is a process improvement methodology, typically based on the Toyota Production System, that seeks to minimize waste, shorten lead times, and maximize efficiency. Lean:

- Reduces lead time

- Increases throughput

- Eliminates waste

- Provides more value to customers

- Creates greater profitability

- Improves delivery time

The Lean Roadmap

Lean uses the same DMAIC acronym as Six Sigma Where you Define, Measure, Analyze, Improve, and Control. The difference is that you use these steps on a process rather than on a specific chronic problem. The Lean roadmap goes as follows:

Define Value

- Define stakeholder value and CTQs

- Define customer demand

- Map high-level process

- Assess for 6S implementation

Measure Value

- Measure customer demand

- Plan for data collection

- Validate the measurement system

- Create a value stream map

- Determine pace, takt time, and manpower

- Identify replenishment and capacity constraints

- Implement S1-S3 of 6S

Analyze Process Flow

- Analyze the value stream map

- Analyze process and load capacity

- Perform VA/NVA decomposition analysis

- Apply Lean problem solving to solve for special causes

Improve Process Pull

- Conduct rapid improvement events

- Design the process changes and flow

- Feed, balance, and load the process

- Standardize work tasks

- Implement new processes

Control the Process

- Stabilize and refine the value stream

- Complete process and visual controls

- Identify mistake-proofing opportunities

- Implement S4-S6 of 6S

- Monitor results and close out the project

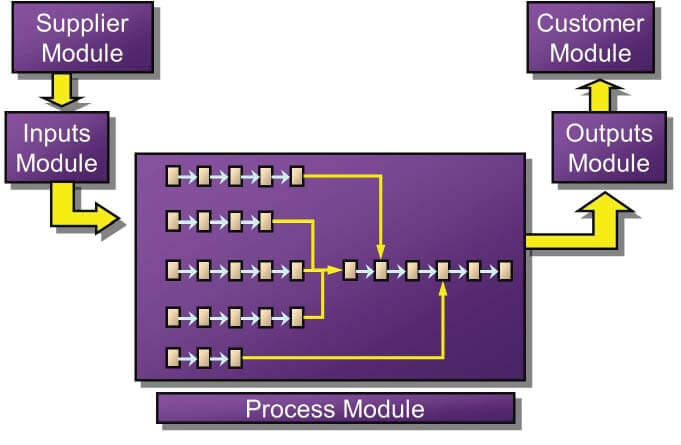

The Value Stream

- Lean Six Sigma projects can begin by selecting a problem to solve or a value stream to improve.

- A value stream differs from a problem solving activity. It is more encompassing because it includes all the activities required to bring goods or services from conception to commercialization.

- A value stream can include detailed design, order taking, scheduling, processing, and delivery or a sub-set of it.

- Understanding the value stream allows one to see value-added steps, non-value added steps, and non-value added but necessary steps.

The image above displays a very basic value stream map, a tool which shows all steps in a process.